Spring Washer

As a professional Taiwanese hardware manufacturer, supplier and exporter, our professional production equipment enables

us to provide customized design and product OEM services.

Our foundry service has won unanimous praise from customers, and is also well received by customers in Taiwan. We look

forward to cooperating with more global customers for common development and mutual benefit.

According to the detailed drawing provided by the customer, including the appearance, logo and size of the washer. We will

use the best raw materials to produce high-quality products for you

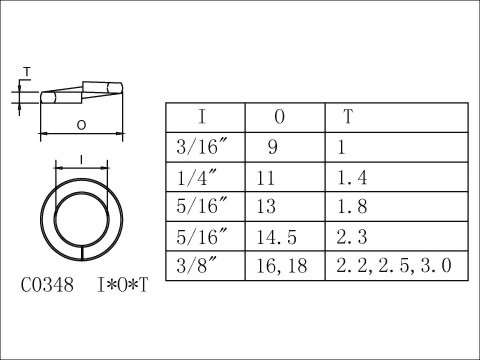

|

Product |

Color |

Specification |

||

|

Inner diameter |

Outer diameter |

Thickness |

||

|

Spring Washer |

Black Oxide Black Zinc BK Yellow Zinc Nickel Polish Brass Antique Copper Zinc |

3/16” |

9 m/m |

1 m/m |

|

1/4” |

11 m/m |

1.4 m/m |

||

|

5/16” |

13 m/m |

1.8 m/m |

||

|

14.5 m/m |

2.3 m/m |

|||

|

3/8” |

18 m/m |

2.5 m/m |

||

Washer (spring) washer, circlip is a resilient cushion or lock washer that prevents bolts from loosening. The working principle of the lock

washer is very simple. It consists of two washers.

The outer side is a radial convex surface, and the inner side is a helical tooth surface. When assembling, the inner side helical tooth surfaces

face each other, and the outer radial convex surface is in occlusal state with the contact surfaces at both ends.

And when the bolt tends to loosen, only allow the relative displacement between the inner helical tooth surfaces of the two washers to generate

lifting tension, so as to achieve 100% locking.